I understand the critical role that technical drawings play in the manufacturing process. These drawings are the blueprint of our work, guiding every cut and operation. In this listicle, we’ll explore what you need to keep in mind when dealing with machining technical drawings, ensuring you’re on the right path to precision and excellence.

1. The Foundation of Precision Machining

Before we dive into the intricacies of machining technical drawings, let’s establish a solid foundation. Technical drawings are the fundamental communication tool between engineers, machinists, and CNC operators. They provide a clear representation of the part’s design, allowing for precise and consistent manufacturing.

Technical drawings are a universal language, enabling professionals worldwide to understand the specifics of a component’s design and production. They include vital information like dimensions, tolerances, material specifications, and geometric tolerances. It’s essential to be well-versed in these aspects to ensure your projects meet the highest standards of quality and accuracy.

2. Types of Technical Drawings

Understanding the various types of technical drawings is crucial. Different drawings serve different purposes, and knowing which one to use is key to a successful project. Let’s explore some common types:

a. Orthographic Drawings

Orthographic drawings, also known as multiview projections, are the foundation of technical drawing. They present a 2D representation of a 3D object using multiple views, such as front, top, and side. This method is essential for understanding the overall shape and size of a part.

b. Isometric Drawings

Isometric drawings provide a 3D representation of an object on a 2D surface. They are useful for visualizing a part from various angles, which can aid in understanding its spatial characteristics. This type of drawing is especially valuable when dealing with complex geometries.

3. Tolerances: The Devil in the Details

Tolerances are a critical aspect of technical drawings. They specify the acceptable variations in dimensions, ensuring that a part functions correctly and fits seamlessly with other components. Understanding and correctly interpreting tolerances is vital in precision machining.

A common way to express tolerances is through the Geometric Dimensioning and Tolerancing (GD&T) system. This standardized system uses symbols to define the allowable variations in size, form, and orientation of features on a part. Mastering GD&T can be a game-changer in ensuring your machined parts meet the required specifications.

4. Material Selection

The choice of materials plays a significant role in the success of a machining project. Technical drawings should clearly specify the type of material required for a component. Whether it’s aluminum, steel, titanium, or other materials, understanding their properties, such as strength, heat resistance, and machinability, is essential.

It’s also crucial to consider material traceability and quality. High-quality materials are the foundation of durable and reliable parts. Your typical client, like Michael, values quality and reliability, so delivering parts made from superior materials will set you apart.

5. Surface Finish and Coatings

Technical drawings should indicate the required surface finish for a part. This detail affects the part’s appearance, performance, and durability. Whether it’s a polished surface for aesthetics or a specific roughness for functional purposes, clear instructions are essential.

Additionally, some components may require coatings for protection against corrosion or to enhance certain properties like lubricity or electrical conductivity. Understanding the coatings specified in the drawing and their application processes is vital to meet your client’s expectations.

6. CNC Machining Techniques

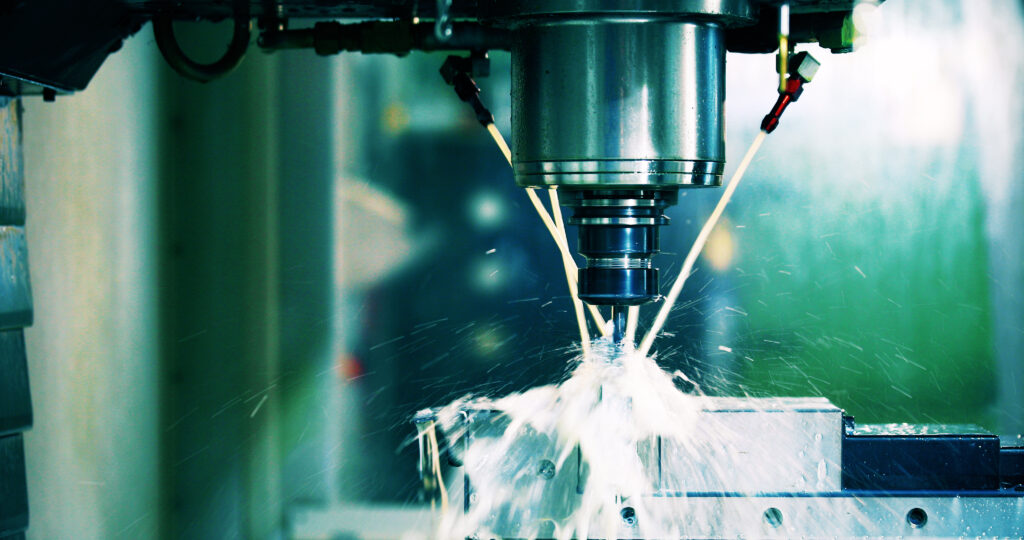

In the world of precision CNC machining, your understanding of machining techniques is paramount. The technical drawings should align with the chosen machining processes, such as turning, milling, drilling, or grinding. Knowing which tools and strategies to employ for each feature on the part is vital for achieving accuracy.

CNC machining offers the advantage of automation and precision, but it requires expertise to program the machines correctly. Your client, like Michael, values transparency about your production processes and expects advanced technology, such as CNC machining, to ensure precision and accuracy in the parts you deliver.

7. Design for Manufacturability

A well-designed part is not only functional but also cost-effective to produce. Technical drawings should consider design for manufacturability (DFM) principles. This means that the design should be optimized for efficient and cost-effective manufacturing.

DFM involves aspects like minimizing complex features, reducing tight tolerances where unnecessary, and selecting readily available materials. By embracing DFM principles, you can provide your clients with cost-effective solutions that don’t compromise quality.

8. Quality Control and Inspection

Once the machined parts are ready, quality control and inspection are critical. Technical drawings should include inspection guidelines and references to ensure that the finished parts meet the required specifications. This step is crucial in maintaining your reputation for quality and reliability.

9. Documentation and Traceability

Every step of the machining process should be well-documented. Technical drawings should reference relevant standards, procedures, and specifications. This documentation not only aids in quality control but also ensures traceability, which is vital in case issues arise later on.

10. Collaboration and Communication

Finally, effective communication is the glue that holds the entire process together. Collaboration between engineers, machinists, and CNC operators is essential. Technical drawings should facilitate clear communication, ensuring that everyone involved understands the project’s requirements and goals.

In conclusion, Machining Technical Drawings is a multifaceted topic that demands attention to detail and a deep understanding of precision machining. Your typical client, like Michael, seeks quality, transparency, and customized solutions. By mastering the intricacies of technical drawings, you can meet and exceed their expectations, building lasting relationships that benefit both parties.