Aerospace components require materials that combine lightweight, high strength, corrosion resistance, and temperature tolerance. The best materials depend on whether the part is structural, engine-related, or interior.

Here’s a breakdown of commonly used materials for aerospace applications:

🛠️ 1. Metals and Alloys

a. Aluminum Alloys (e.g., 2024, 6061, 7075)

- Advantages: Lightweight, strong, corrosion-resistant, easy to machine.

- Uses: Fuselage, wings, interior structures, brackets.

- Example: 7075-T6 aluminum is used in airframes due to its excellent strength-to-weight ratio.

b. Titanium Alloys (e.g., Ti-6Al-4V)

- Advantages: High strength, excellent corrosion resistance, withstands high temperatures.

- Uses: Jet engine parts, landing gear, fasteners, and structural frames.

- Note: Expensive, but crucial where performance outweighs cost.

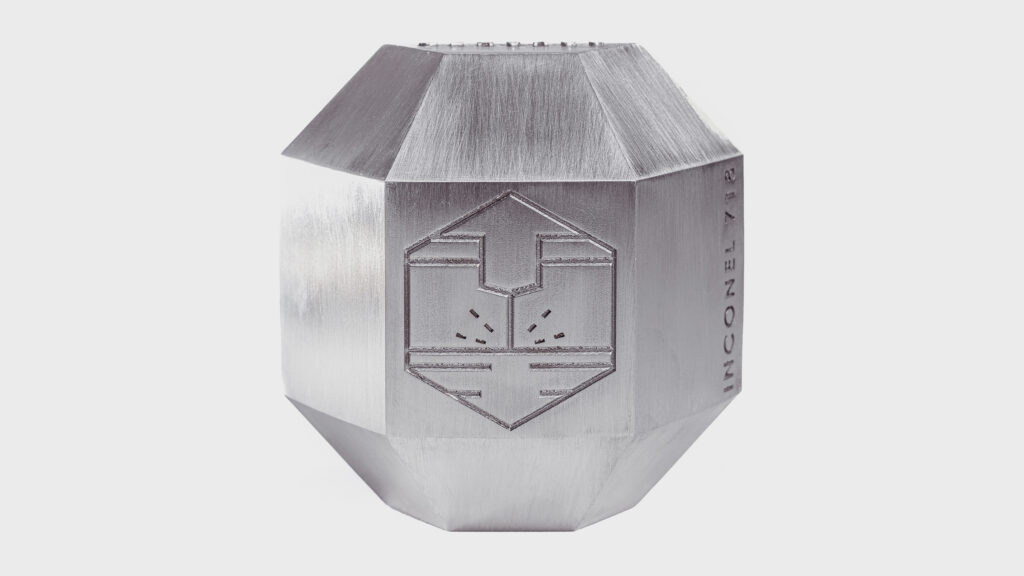

c. Nickel-Based Superalloys (e.g., Inconel, Hastelloy)

- Advantages: Exceptional strength at very high temperatures.

- Uses: Turbine blades, engine exhaust systems, and heat exchangers.

d. Steel Alloys (e.g., Maraging Steel, 4340 Steel)

- Advantages: Extremely strong and tough, good fatigue resistance.

- Uses: Landing gear, shafts, and high-load components.

- Note: Heavier than aluminum or titanium — used selectively.

🧬 2. Composite Materials

a. Carbon Fiber Reinforced Polymer (CFRP)

- Advantages: Very high strength-to-weight ratio, fatigue resistance, corrosion resistance.

- Uses: Aircraft fuselage, wings, control surfaces, space structures.

- Example: Boeing 787 Dreamliner’s fuselage is over 50% composite by weight.

b. Glass Fiber Reinforced Polymer (GFRP)

- Advantages: Low cost, good strength, electrical insulation.

- Uses: Radomes, interior panels, fairings.

c. Kevlar (Aramid Fiber Composites)

- Advantages: Impact and vibration resistance, light weight.

- Uses: Helicopter blades, ballistic protection, radomes.

🔥 3. High-Temperature Ceramics and Coatings

a. Silicon Carbide (SiC), Zirconia, Alumina

- Advantages: Extreme temperature resistance, low thermal expansion.

- Uses: Thermal protection systems, engine coatings, rocket nozzles.

b. Thermal Barrier Coatings (TBCs)

- Advantages: Protect metal components from high heat in turbines.

- Common Coating: Yttria-Stabilized Zirconia (YSZ).

🧩 4. Emerging Materials

- Metal Matrix Composites (MMC): Combine metals with ceramics for strength and stiffness.

- Additively Manufactured Alloys: 3D-printed titanium or Inconel parts for lightweight, complex geometries.

- Graphene-Enhanced Composites: Improving conductivity and mechanical strength (still experimental).