Both overmolding and insert molding offer several benefits in the manufacturing of plastic parts:

Benefits of Overmolding:

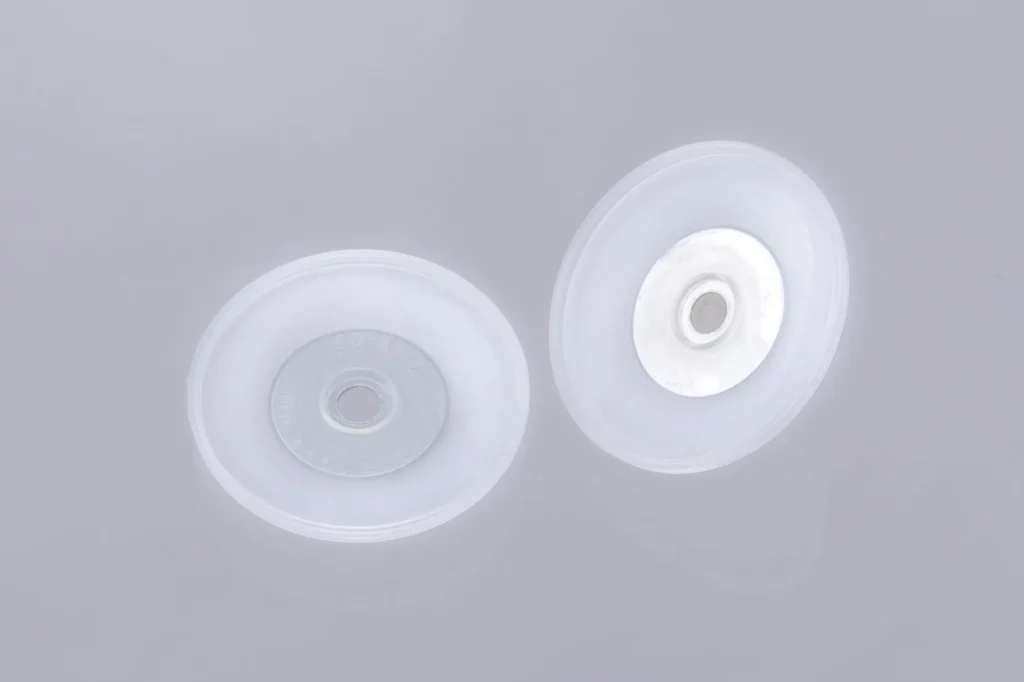

1.Enhanced Product Functionality: Overmolding allows for the integration of multiple materials with different properties into a single part, enabling enhanced functionality. For example, a rigid plastic base can be overmolded with a soft rubber material to create a comfortable and ergonomic grip.

2.Improved Aesthetics: Overmolding enables the addition of decorative elements, textures, or multiple colors to a part, enhancing its visual appeal. This can be particularly useful for consumer products where aesthetics play a crucial role in product differentiation.

3.Increased Durability: By encapsulating a rigid core with a soft or protective outer layer, overmolding can improve the durability and impact resistance of parts, making them more resistant to wear, tear, and environmental factors.

4.Reduced Assembly Steps: Overmolding eliminates the need for separate assembly steps that would otherwise be required to combine multiple components, streamlining the manufacturing process and reducing labor costs.

5.Improved Ergonomics: Overmolding allows designers to create parts with ergonomic shapes and contours, enhancing user comfort and usability.

Benefits of Insert Molding:

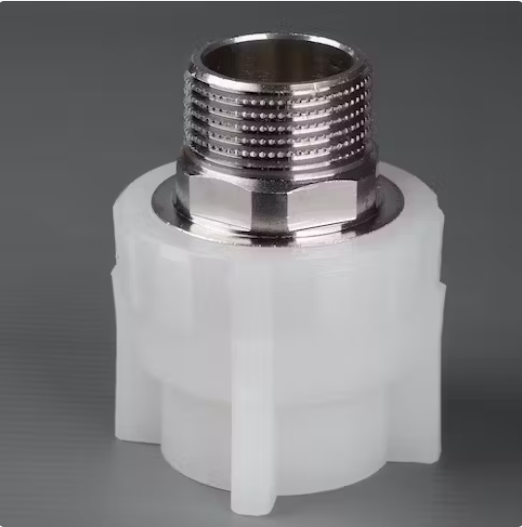

1.Enhanced Part Strength: Insert molding enables the creation of parts with integrated inserts, resulting in stronger and more robust components compared to assemblies of separate parts. The bond between the insert and the molded plastic provides added strength and stability.

2.Cost Savings: Insert molding can reduce costs by eliminating the need for additional assembly steps and fasteners required to attach inserts to parts. It also reduces material waste by precisely molding plastic around inserts, minimizing excess material.

3.Design Flexibility: Insert molding offers designers greater flexibility in creating complex parts with integrated features. Inserts can be made from a wide range of materials, allowing for combinations of materials with different properties in a single part.

4.Improved Electrical Performance: In applications where electrical conductivity or insulation is required, insert molding allows for the integration of metal contacts, wires, or other electrical components directly into plastic parts, ensuring reliable electrical performance.

5.Streamlined Production: By incorporating multiple components into a single molded part, insert molding simplifies the production process, reducing lead times and improving overall efficiency.

Overall, both overmolding and insert molding offer advantages in terms of product performance, aesthetics, cost-effectiveness, and manufacturing efficiency, making them valuable techniques in the plastic injection molding industry.