Knurling is a manufacturing process used to create a textured pattern of straight, angled, or crossed lines on the surface of a material (usually metal).

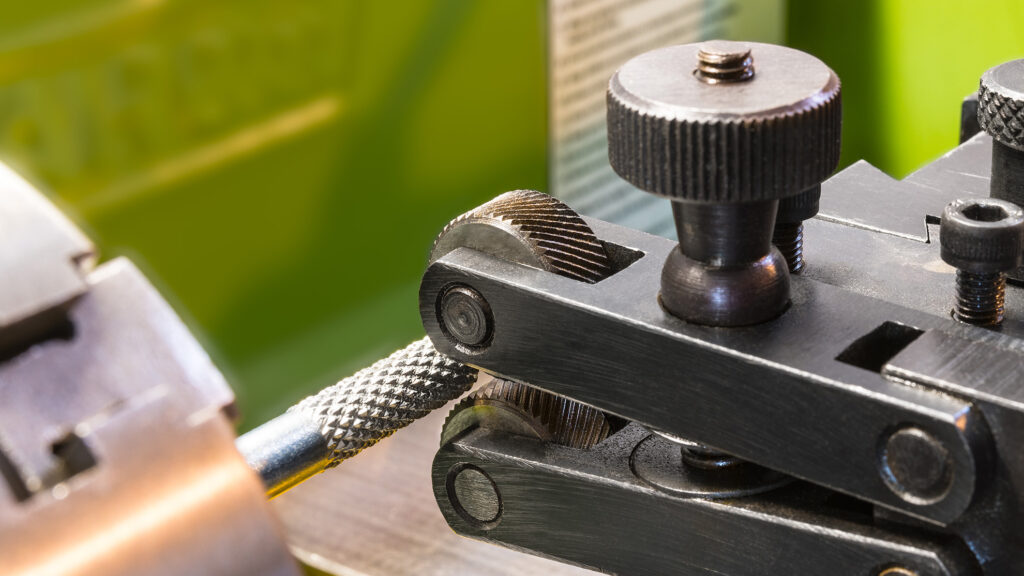

It is typically done on a lathe using a hardened tool called a knurling tool that presses against the workpiece as it rotates, displacing the material to form a raised pattern.

Key Points:

- Purpose:

- Provides a better grip on cylindrical parts such as tool handles, knobs, or fasteners.

- Used for aesthetic finishes and decorative purposes.

- Can be used to create an interference fit (slightly oversized surface to press-fit into another part).

- Patterns:

- Straight – parallel lines, often for decorative or functional sliding surfaces.

- Diagonal/Angled – lines at an angle, sometimes for grip.

- Diamond (Cross) – crisscross pattern, most common for non-slip grip.

- Applications:

- Handles of tools (e.g., pliers, screwdrivers).

- Knobs and grips on instruments or machines.

- Metal parts that require press-fit assembly.

In short: Knurling is the process of rolling a patterned tool onto a workpiece to produce textured grips or press-fit surfaces.

1. Setup

- The workpiece (usually a cylindrical bar) is mounted on a lathe.

- A knurling tool (with hardened, patterned rollers) is positioned against the workpiece.

- Common knurling tools have two or more rollers that press simultaneously for balance.

2. Engagement

- The lathe rotates the workpiece.

- The knurling tool is pressed against the surface with controlled pressure/feed.

- The rollers have a pre-cut pattern (straight, diagonal, or diamond).

3. Material Flow

- As the tool rolls along the rotating workpiece:

- The pattern on the rollers impresses into the surface.

- Metal flows plastically (like clay being pressed), forming raised ridges and grooves.

- The resulting pattern is a replica of the knurling tool’s geometry.

4. Result

- The surface now has a textured pattern that:

- Improves grip (non-slip).

- Can slightly increase diameter for press fits.

- Provides a decorative finish.

⚙️ Key Parameters

- Workpiece speed (RPM): Lower than normal turning, to avoid tool chatter.

- Feed rate: Adjusted so the roller pattern meshes evenly—otherwise, you get a “double tracking” defect.

- Pressure: Sufficient to plastically deform the material without excessive wear on tool or workpiece.

✅ In simple terms:

Knurling works by pressing hardened patterned rollers against a rotating workpiece, displacing the metal surface into a matching textured design.