As an enthusiast in the field of custom manufacturing metal and plastic parts, I have witnessed the numerous benefits that this industry offers. With my expertise and experience, I can confidently share valuable insights about the advantages of custom manufacturing. Let’s dive into the world of precision and customization!

Listicle Item 1: Endless Possibilities with Customization

One of the greatest advantages of custom manufacturing metal and plastic parts is the ability to achieve unparalleled levels of customization. Unlike off-the-shelf parts, custom-made components are tailored specifically to meet your unique requirements. Whether you need a specialized shape, size, or functionality, custom manufacturing allows you to bring your vision to life.

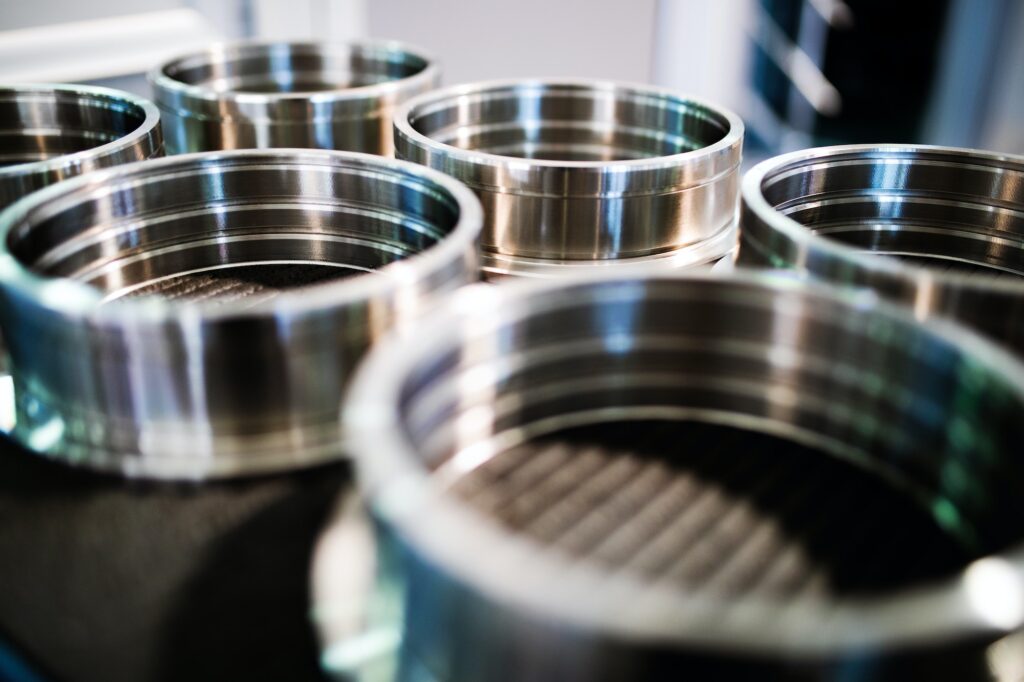

From intricate designs to complex geometries, custom parts can be created with precision and accuracy using advanced technologies such as CNC machining. This level of customization empowers engineers and designers to explore new possibilities, improve product performance, and enhance overall efficiency.

Listicle Item 2: Enhanced Product Quality and Performance

When it comes to metal and plastic parts, quality is paramount. Custom manufacturing ensures that each component is crafted with meticulous attention to detail and adheres to the highest industry standards. By working closely with manufacturers like CNCPRECISION, you can expect superior quality products that meet or exceed your expectations.

Custom parts are manufactured using top-quality materials, selected based on your specific requirements. Whether you need parts that can withstand extreme temperatures, resist corrosion, or have exceptional strength, custom manufacturing allows for material selection that precisely matches your needs.

Furthermore, customization enables engineers to optimize the design for enhanced performance. By fine-tuning factors such as weight, structural integrity, and compatibility, custom parts can significantly improve the efficiency and reliability of your products.

Listicle Item 3: Cost-Effectiveness through Efficiency

Contrary to the misconception that custom manufacturing is prohibitively expensive, it can actually be a cost-effective solution in the long run. While the initial investment may be higher compared to mass-produced parts, the benefits far outweigh the costs.

Custom manufacturing allows for efficient use of materials, reducing waste and minimizing expenses. With the ability to optimize designs and eliminate unnecessary features, you can achieve better cost efficiency without compromising on quality or functionality.

Additionally, custom parts can help streamline assembly processes. By precisely fitting into the intended application, these parts reduce the need for additional modifications or adjustments, saving time and labor costs. The improved compatibility and seamless integration of custom parts enhance overall productivity and minimize potential errors during assembly.

Listicle Item 4: Accelerated Time-to-Market

In today’s fast-paced business environment, time is of the essence. Custom manufacturing offers a significant advantage by accelerating the time-to-market for your products. By collaborating closely with CNCPRECISION, you can streamline the production process, reduce lead times, and gain a competitive edge.

Unlike waiting for off-the-shelf parts, which may not perfectly match your requirements, custom manufacturing allows you to promptly receive components tailored to your specifications. This quick turnaround time empowers you to respond swiftly to market demands, launch products faster, and stay ahead of the competition.

Listicle Item 5: Strengthened Supply Chain Relationships

Collaborating with a reliable custom manufacturing partner like MIMCNC fosters strong and long-lasting relationships within your supply chain. By working closely together, you can establish

trust, improve communication, and develop a deeper understanding of your specific needs.

Custom manufacturers who prioritize customer satisfaction, like us, are committed to providing exceptional service and addressing any concerns promptly. This collaborative approach ensures that your requirements are met consistently, and you receive personalized support throughout the manufacturing process.

Furthermore, when you have a trusted custom manufacturing partner, you can rely on their expertise and industry knowledge. They can offer valuable insights, recommend design optimizations, and suggest material alternatives that align with your goals. This partnership not only strengthens your supply chain but also contributes to the success of your business.