Sheet Metal Service

Sheet metal bending is a manufacturing process used to transform flat sheets of metal into 3D shapes. A bending machine presses a punch onto the sheet, which causes it to bend to the desired angle. Metal fabrication companies offer sheet metal bending services to produce custom parts, prototypes, or large production runs of metal components. The cost depends on factors such as complexity, quantity, and metal type.

The accuracy of the bending process depends on the skill of the machine operator and the quality of the equipment used. Metal bending machines can bend metal at different angles, depending on the shape and size of the punch and die.

Available materials for Sheet Metal

| Aluminum | Stainless steel | Mild steel | Copper |

|---|---|---|---|

| 5052 | 304 | 1018 | C110 |

| 5754 | 316L |

- Please feel free to contact us If you require a custom material.

Tolerances

| Feature | Tolerance |

|---|---|

| Cutting feature | ± .00787’’ (0.2 mm) |

| Bend angle | ± 1.0° |

| Bend to edge | +/- 0.010” (0.254mm) |

Process

| Name | Description | Allowable sheet thickness |

|---|---|---|

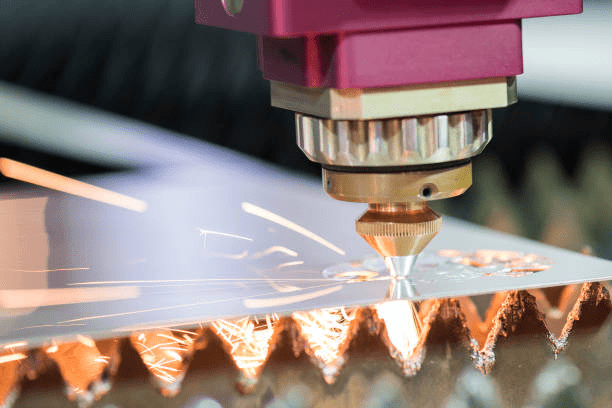

| Laser cutting | This manufacturing process uses a high-power laser beam to cut a material sheet. | 1-6mm (depending on material) |

| Bending | This manufacturing process uses dies to produce a U-shape, V- shape or channel shape along a straight axis in ductile materials. | 1-6mm (depending on material) |

Sheet Metal Products

Previous

Next