Liquid silicone rubber (LSR) molding is a process used to create parts and components made from silicone rubber. Here’s a simplified overview of how it works:

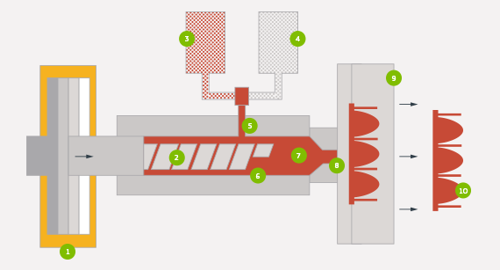

Mold Preparation: The process starts with the preparation of the mold. The mold typically consists of two halves, which can be made of metals like aluminum or steel. These molds are precision-machined to the exact specifications of the desired part.

Injection: In the injection phase, the two halves of the mold are clamped together, creating a cavity into which the liquid silicone rubber is injected. The silicone rubber is typically stored in barrels and pumped into the mold using specialized equipment.

Curing: Once the mold cavity is filled with the liquid silicone rubber, the material undergoes curing. Curing can occur through various methods, such as exposure to heat or chemical catalysts. This process causes the silicone rubber to solidify and take the shape of the mold cavity.

Cooling and Solidification: After curing, the mold is cooled to help the silicone rubber solidify further and reach its final form. The cooling process may involve air cooling or the use of cooling channels within the mold.

Part Removal: Once the silicone rubber has completely solidified, the mold is opened, and the newly formed part is removed. Depending on the complexity of the part and the design of the mold, additional steps such as trimming or post-curing may be necessary to achieve the desired final product.

Repetition: The entire process is then repeated for each new part. LSR molding is capable of producing high volumes of parts with consistent quality and precision.

LSR molding offers several advantages, including high precision, excellent part quality, resistance to extreme temperatures, chemical inertness, and biocompatibility, making it suitable for a wide range of applications across industries such as automotive, electronics, medical devices, and consumer products.