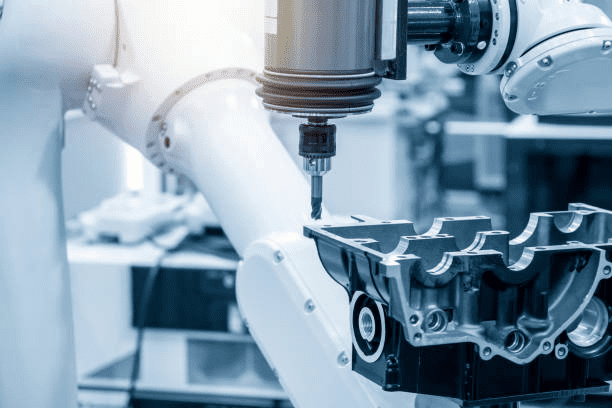

Die Casting Service

Die casting service is a manufacturing process used to produce complex metal parts with high precision and repeatability. The process involves injecting molten metal into a mold, known as a die, under high pressure. The metal quickly solidifies and takes on the shape of the die, creating a near-net-shape part that requires minimal finishing.

It’s commonly used in the production of a wide range of products, including automotive parts, consumer electronics, and medical devices. The process allows for the creation of parts with intricate designs and tight tolerances, making it a popular choice for high-volume production runs.

The die casting process can use a variety of metals such as aluminum, zinc, and magnesium, each with their own unique properties and advantages. Die casting service providers can offer value-added services such as machining, finishing, and assembly to provide customers with a finished product that meets their specific requirements.

Materials

ALUMINUM

We have aluminum die casting machines ranging from 400 to 3,000 tons, giving us the ability to provide a large range of aluminum casting sizes and weights to serve nearly any industry and application. Aluminum die cast parts are lightweight, corrosion resistant and have a wide range of surface finishing options.

MAGNESIUM

We have extensive magnesium die casting knowledge and expertise, partnering with customers on the distinctive benefits of magnesium die casting to suit their needs. Magnesium offers a perfect combination of light weight, rigidity and resistance to wear for diverse die cast part applications.

ZINC

We offer a variety of zinc die casting approaches that range from the ability to produce small, miniature zinc die castings to larger, conventional castings. Zinc provides unique advantages in many die casting applications that include a combination of strength, ductility, impact strength, finishing characteristics and tooling that has high resistance to catastrophic failure.