Imagine you have a new product design in mind, and you’re considering the best manufacturing method to bring it to life. Two popular options that come to mind are CNC machining and 3D printing. Both offer unique advantages, but which one is the right choice for your specific needs? In this blog post, we will compare CNC machining and 3D printing to help you make an informed decision.

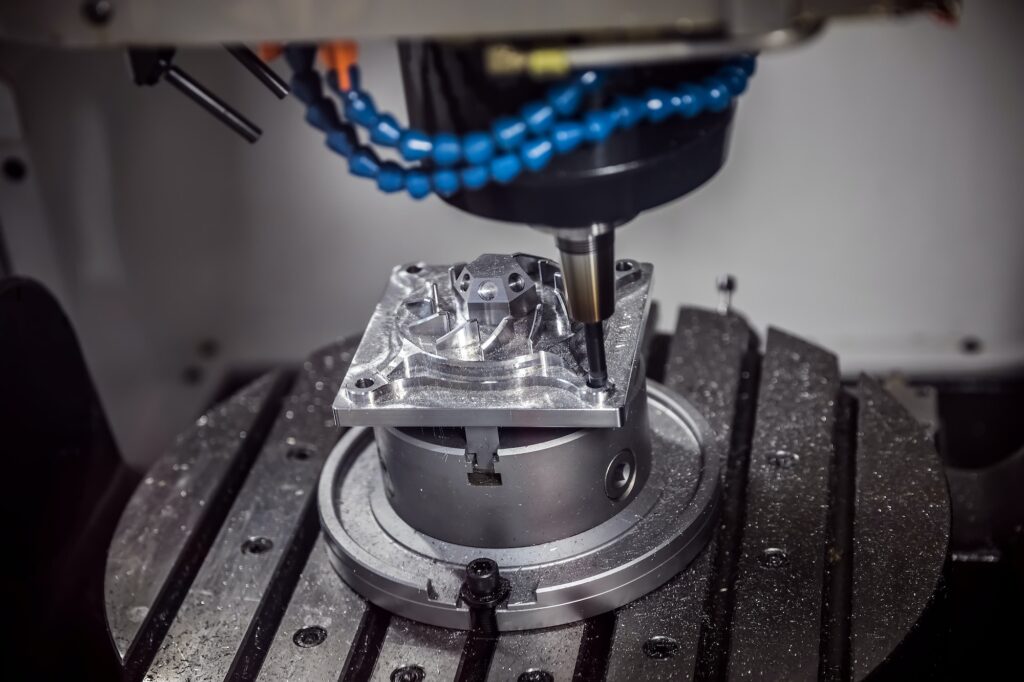

CNC Machining: Precision and Versatility

CNC machining, or Computer Numerical Control machining, is a subtractive manufacturing process that uses computer-controlled machines to shape and cut materials into the desired shape. It offers exceptional precision and accuracy, making it an ideal choice for producing high-quality metal parts with tight tolerances. CNC machining supports a wide range of materials, including metals like aluminum, steel, and titanium.

With CNC machining, you can create complex geometries and intricate designs that meet your exact specifications. The process involves programming the machine to follow precise instructions, resulting in consistent and repeatable parts. CNC machining is widely used in industries such as aerospace, automotive, and medical, where precision and reliability are paramount.

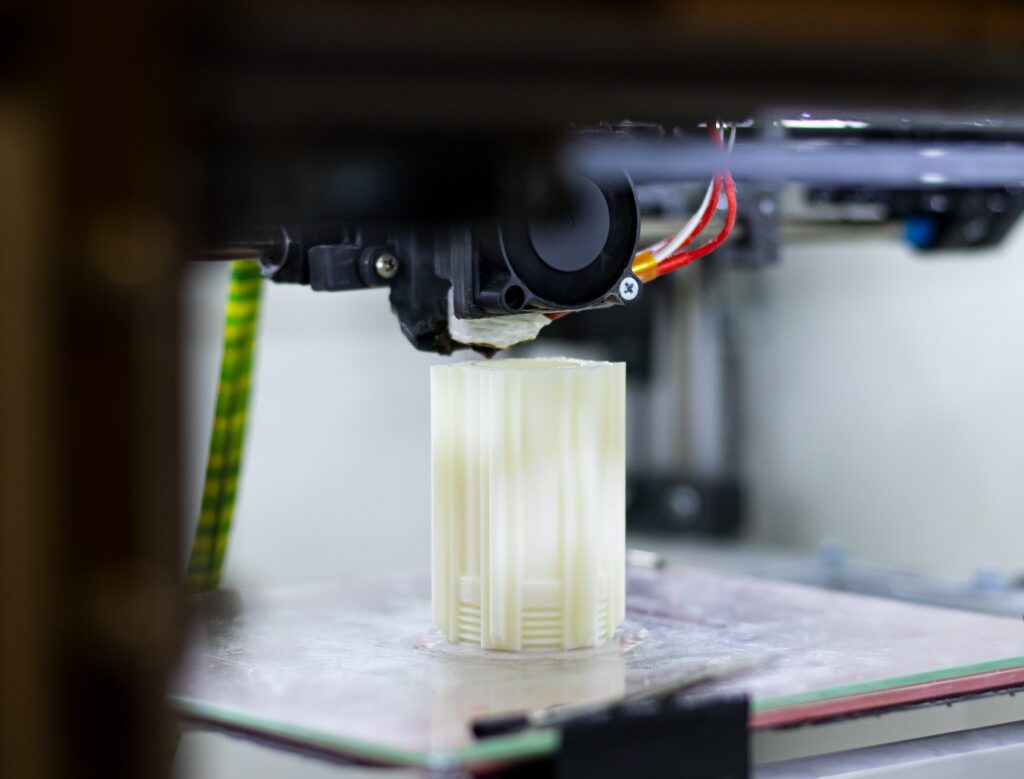

3D Printing: Rapid Prototyping and Design Freedom

On the other hand, 3D printing, also known as additive manufacturing, is a process that builds objects layer by layer using a digital model. It offers the advantage of rapid prototyping and allows for complex geometries that are difficult to achieve with traditional manufacturing methods. 3D printing is commonly used in product development, architectural modeling, and customized manufacturing.

3D printing provides design freedom, enabling you to create intricate shapes and internal structures that are challenging to produce with CNC machining. It supports a variety of materials, including plastics, metals, and even composites. This versatility makes 3D printing an excellent choice for quick prototyping, low-volume production, and customized one-off parts.

Which Method is Right for You?

Factors to Consider

Choosing between CNC machining and 3D printing depends on several factors:

- Complexity of Design: If your design requires intricate details and tight tolerances, CNC machining is the better option due to its precision capabilities. However, if you have a complex, organic shape, or need to create prototypes quickly, 3D printing may be the more suitable choice.

- Material Requirements: Consider the material properties required for your parts. CNC machining offers a wider selection of materials, including metals, making it ideal for applications that demand high strength or durability. 3D printing materials, while continuously advancing, may have limitations in terms of strength and heat resistance.

- Production Volume: If you require a large volume of parts, CNC machining may be more cost-effective in terms of unit price. On the other hand, 3D printing excels in small-batch production or when customization is essential.

Cost Considerations

CNC machining typically involves higher upfront costs due to the need for specialized equipment, tooling, and skilled labor. However, it can offer economies of scale for larger production runs. 3D printing, on the other hand, has lower initial setup costs but may have higher material costs for larger volumes.

Summary

In summary, CNC machining is well-suited for applications that require precise, high-quality metal parts and materials, while 3D printing offers rapid prototyping, design freedom, and versatility for complex geometries and smaller volumes. Consider the specific requirements of your project, including design complexity, material needs, and production volume, to determine which method aligns best with your goals.

Conclusion

When it comes to choosing between CNC machining and 3D printing, there is no one-size-fits-all answer. Each method has its strengths and considerations. By evaluating your project requirements, considering factors like design complexity, material needs, and production volume, you can make an informed decision that aligns with your goals and budget. Remember, we are here to help you navigate through the process and provide the high-quality parts you need for your success.