The highest quality sheet metal products typically come from manufacturers who prioritize precision, durability, and material integrity. Here are some key factors that contribute to top-notch sheet metal products:

1.Material Selection: High-quality sheet metal products start with the selection of premium materials such as stainless steel, aluminum, or titanium. The choice of material depends on the specific requirements of the application, including factors like strength, corrosion resistance, and conductivity.

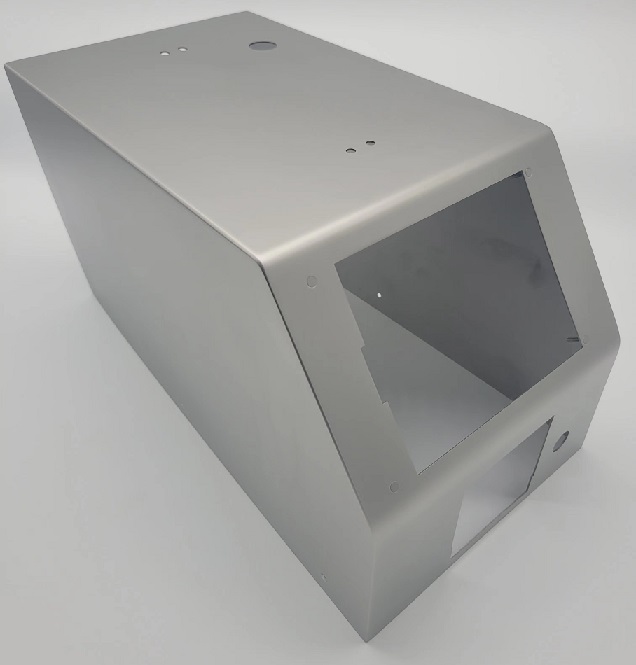

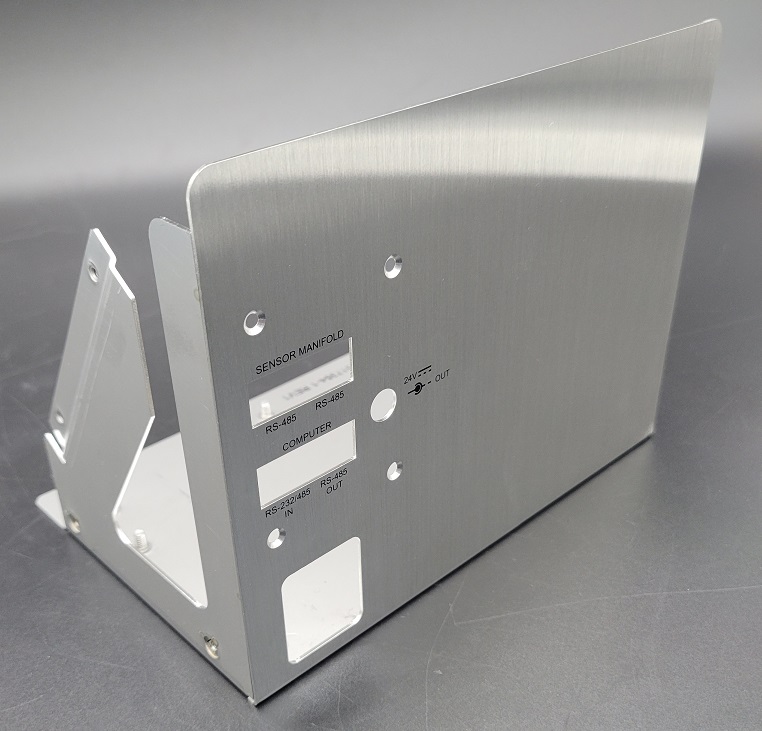

2.Precision Manufacturing: Manufacturers employ advanced machining techniques, including laser cutting, CNC punching, and precision bending, to ensure accuracy and consistency in the fabrication process. Tight tolerances and meticulous attention to detail are essential for producing flawless sheet metal components.

3.Surface Finish: Quality sheet metal products undergo surface treatments such as powder coating, anodizing, or plating to enhance their appearance and protect against corrosion. A smooth, uniform finish not only improves aesthetics but also extends the lifespan of the product.

4.Quality Control: Rigorous quality control measures, including dimensional inspections, material testing, and performance evaluations, are integral to maintaining the highest standards throughout the manufacturing process. Regular audits and certifications demonstrate a commitment to quality assurance.

5.Customization Capabilities: Top manufacturers offer customization options to meet the unique specifications of each customer. Whether it’s complex geometries, intricate designs, or specialized coatings, the ability to tailor sheet metal products to individual requirements sets industry leaders apart.

6.Durability and Longevity: High-quality sheet metal products are built to last, with superior strength, resilience, and resistance to wear and tear. Attention to material thickness, reinforcement, and structural integrity ensures reliability and longevity in demanding environments.

7.Environmental Sustainability: Increasingly, manufacturers are adopting sustainable practices such as using recycled materials, minimizing waste, and optimizing energy efficiency in their production processes. Eco-friendly initiatives not only reduce the environmental footprint but also contribute to the overall quality and reputation of the product.