Greetings, fellow enthusiasts of precision manufacturing! I’m here to delve into the intriguing world of machining. Today, let’s unravel the mysteries behind the different axes in machining – 3-axis, 4-axis, and 5-axis – and discover how they impact the quality, intricacy, and efficiency of our precision metal parts.

1. Understanding the Basics: What Are 3-Axis, 4-Axis, and 5-Axis Machining?

Before we dive into the nitty-gritty details, let’s establish a solid foundation. In machining, the number of axes refers to the number of directions in which the cutting tool can move. It’s like a ballet of movement, shaping raw material into a masterpiece. Here’s a brief breakdown:

- 3-Axis Machining: This is where it all begins. Imagine a machine tool that can move its cutting tool in three directions: up and down (vertical), side to side (horizontal), and front to back (longitudinal). It’s like having three artists paint on different sides of a canvas.

- 4-Axis Machining: Now, picture adding a dash of complexity. In 4-axis machining, the cutting tool can not only move vertically, horizontally, and longitudinally but can also rotate around a specific axis. This rotational freedom adds a layer of intricacy to the process.

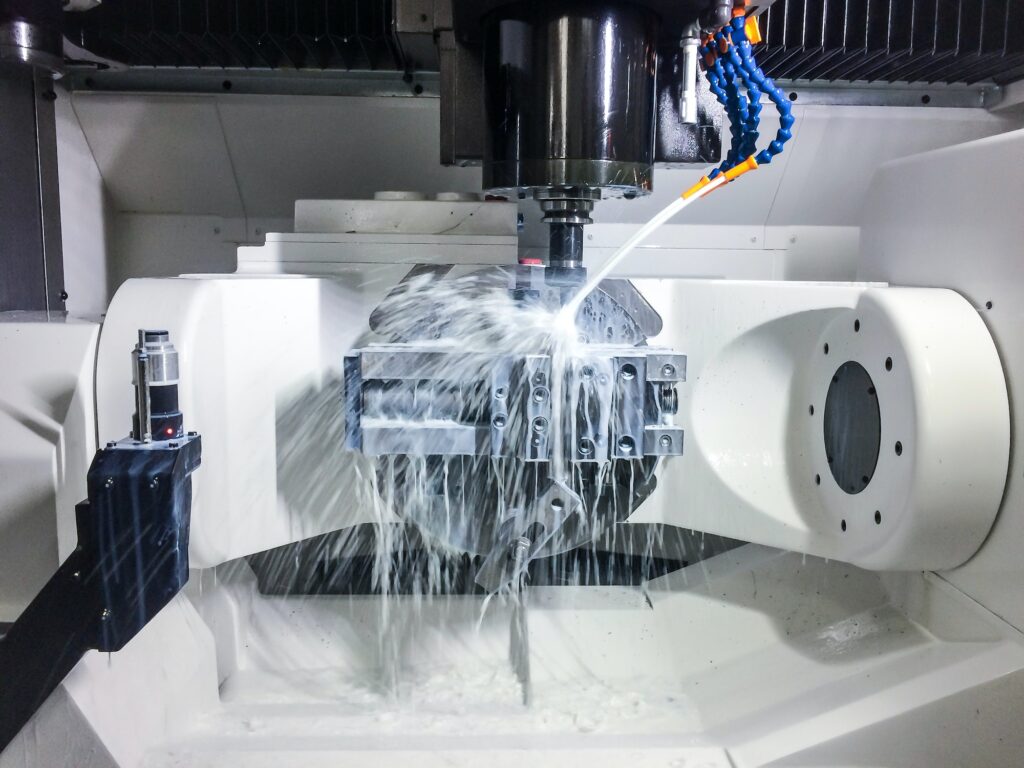

- 5-Axis Machining: Here comes the pinnacle of precision. In 5-axis machining, the cutting tool can perform all the movements of 3-axis and 4-axis machining but can also tilt and swivel. This opens up a world of possibilities, enabling the creation of highly intricate and complex geometries.

2. The Advantages and Limitations of Each Axis Configuration

Let’s break down each axis configuration to understand when and why they shine.

3-Axis Machining: The Foundation of Precision

3-axis machining is like the backbone of precision manufacturing. It’s reliable, efficient, and ideal for producing relatively simple parts. The tool movement is straightforward, making it perfect for components that don’t require intricate geometries. However, it might not be the best choice for highly complex or contoured designs, as the tool can’t reach all angles and surfaces.

4-Axis Machining: Adding a Twist

4-axis machining takes a step further by introducing rotational movement. This is excellent for parts that require holes or features at different angles, like spiral staircases or threaded components. The rotational axis enables the cutting tool to access challenging areas, enhancing precision and versatility.

5-Axis Machining: Where Complexity Thrives

Ah, the pinnacle of precision machining – 5-axis. This configuration unlocks the ability to create incredibly intricate shapes and contours with ease. Complex aerospace components, medical implants, and artistic sculptures benefit immensely from 5-axis machining. The tool can approach the material from any angle, reducing the need for multiple setups and enhancing overall accuracy.

3. The Impact on Precision and Efficiency

Let’s talk numbers and results. Each axis configuration has a tangible impact on the precision and efficiency of the machining process.

Precision: Tolerance and Accuracy

- 3-Axis: While precise, it might struggle with tight tolerances and complex geometries. Expect ±0.005 to ±0.01 inches of tolerance, depending on the material and tooling.

- 4-Axis: The added rotation improves precision, reducing the need for repositioning. Tolerances of ±0.002 to ±0.005 inches are achievable.

- 5-Axis: The ultimate precision player. It can achieve tolerances as tight as ±0.001 inches, ensuring intricate designs are flawlessly replicated.

Efficiency: Time Is Money

- 3-Axis: Efficient for simpler parts, but intricate designs might require more setup and longer machining times.

- 4-Axis: The rotational movement reduces setup time and minimizes tool changes. It strikes a balance between efficiency and complexity.

- 5-Axis: While capable of complex designs, it can also significantly reduce machining time by reaching multiple angles in a single setup.

4. Choosing the Right Axis Configuration for Your Project

As an engineer, you’re undoubtedly seeking the perfect match for your project’s needs. Consider these factors when selecting the ideal axis configuration:

- Geometry: The complexity of your part’s design.

- Tolerance: The precision your project demands.

- Material: Some materials are more forgiving than others.

- Volume: The number of parts you need to manufacture.

- Budget: Each axis configuration comes with different costs.

5. Making Waves in Precision Manufacturing

So, what’s the key takeaway for dedicated engineers, who value quality and reliability above all else? The choice of axis configuration depends on the intricacy of your design and the level of precision required. As a professional who understands your needs, I invite you to explore the world of precision metal parts with MIMCNC.

In conclusion, the journey through the dimensions of 3-axis, 4-axis, and 5-axis machining is an exciting one. Each axis configuration brings its own set of advantages and limitations to the table. As we gaze into the future of precision manufacturing, remember that your projects deserve the best. From the sturdy reliability of 3-axis to the complexity of 5-axis, the world of machining offers solutions for every masterpiece you envision.

Are you ready to transform your ideas into meticulously crafted reality? Join hands with MIMCNC, your partner in precision manufacturing excellence.