From Concept to Completion: Discover What the Custom Metal and Plastic Manufacturing Process Looks Like?

Have you ever wondered how those precise and customized metal and plastic parts are manufactured? How does an idea transform into a tangible product that meets your exact specifications? In this blog post, we will take you on a journey through the custom metal and plastic manufacturing process, from concept to completion. So, let’s dive in and explore the fascinating world of precision manufacturing!

The Starting Point: Ideation and Design

Before any manufacturing process begins, it all starts with an idea. It could be a need for a specific component, an improvement on an existing design, or a completely new innovation. This is where collaboration between engineers, designers, and clients plays a crucial role. Through discussions, drawings, and prototyping, the concept starts taking shape.

Once the idea is solidified, it’s time to move on to the design phase. Using advanced computer-aided design (CAD) software, engineers translate the concept into a detailed and precise digital model. This virtual representation allows for thorough analysis, ensuring that all functional and aesthetic requirements are met.

Turning Designs into Reality: Material Selection and Prototype Development

With the design finalized, the next step is selecting the appropriate materials for the project. The choice of materials depends on various factors such as the intended application, required strength, durability, and environmental considerations. Metals like aluminum, stainless steel, and titanium, as well as various types of plastics, are commonly used in custom manufacturing.

Once the materials are selected, a prototype is developed to validate the design and ensure it meets the desired specifications. Prototyping allows for testing and refinement before mass production begins. Advanced technologies like 3D printing or CNC machining are often employed to create accurate prototypes quickly and cost-effectively.

Precision Manufacturing: CNC Machining and Injection Molding

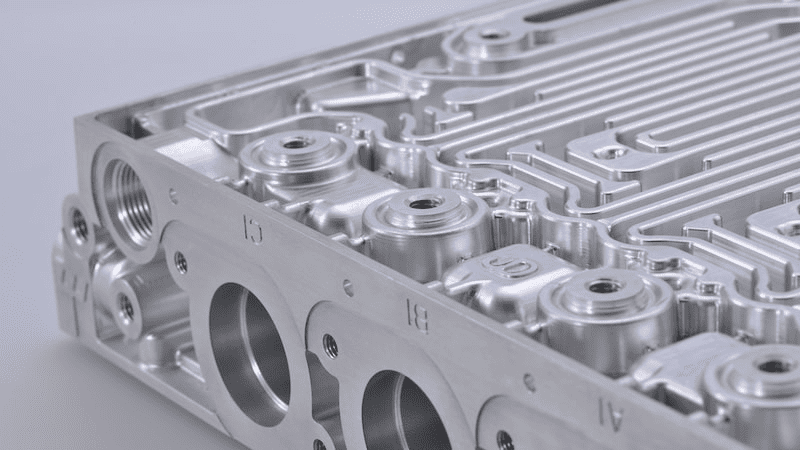

CNC (Computer Numerical Control) machining is a widely used technique in custom metal manufacturing. It involves the use of computer-controlled machines to remove material from a workpiece, transforming it into the desired shape. CNC machines offer unparalleled precision, allowing for complex geometries and tight tolerances to be achieved consistently.

Injection molding, on the other hand, is a common technique used in custom plastic manufacturing. It involves injecting molten plastic into a mold cavity, where it solidifies and takes the shape of the mold. Injection molding enables the production of large quantities of intricate plastic parts with high accuracy and repeatability.

Quality Assurance: Testing and Inspection

Ensuring the quality and integrity of the manufactured parts is a critical step in the custom manufacturing process. Rigorous testing and inspection procedures are employed to verify that the parts meet the required specifications and standards.

Various inspection techniques, such as dimensional checks, surface finish analysis, and material testing, are conducted to validate the quality of the finished products. Advanced measurement tools and equipment, including coordinate measuring machines (CMMs) and optical scanners, aid in the precise evaluation of the parts.

Packaging and Delivery: Ready for the World

Once the parts have successfully passed all quality checks, they undergo thorough cleaning and finishing processes. This includes removing any debris, burrs, or imperfections to ensure a pristine final product. The parts are then carefully packaged, considering factors like protection, labeling, and efficient storage and transportation.

At this stage, the parts are ready to embark on their journey to customers worldwide. As a customer-focused company, we prioritize secure and efficient delivery to ensure the parts reach our clients