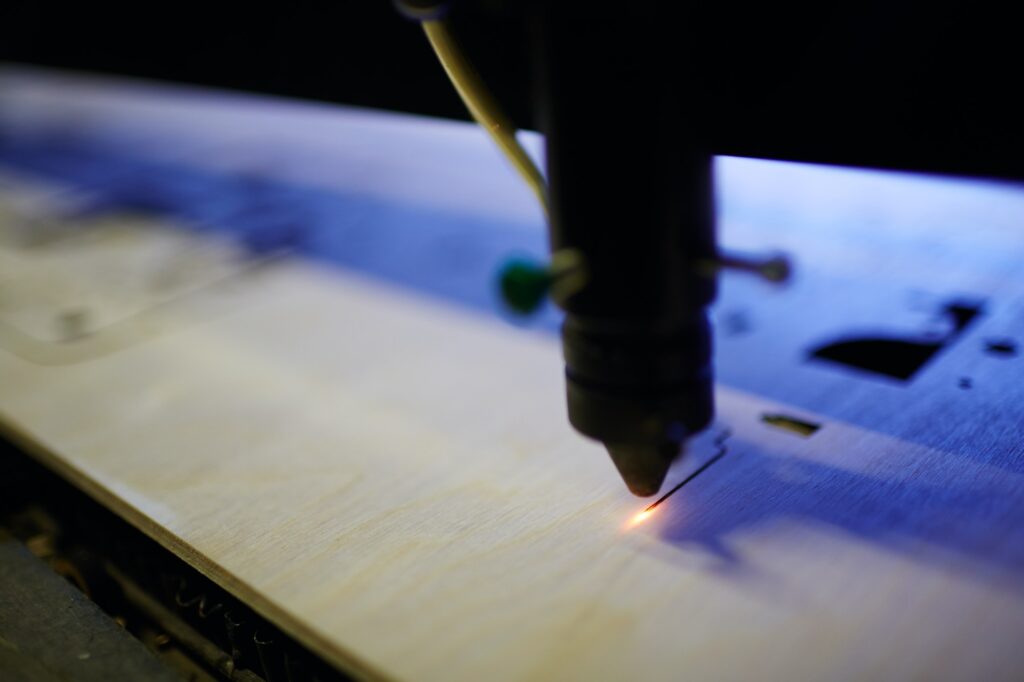

Laser engraving, an art form within the world of precision engineering, involves using a concentrated beam of light to etch or mark surfaces with exceptional precision. It’s not just a technique; it’s a game-changer for industries demanding accuracy and customization in their metal parts.

1. Precision Beyond Measure

Laser engraving boasts unmatched precision, allowing for the creation of intricate designs and markings with microscopic accuracy. According to industry experts, the precision can reach up to 0.005 inches, enabling detailed work on various materials, including metals, plastics, and woods.

2. Versatility Across Materials

This technique isn’t limited by material boundaries. From stainless steel and aluminum to wood and plastics, laser engraving flexes its capabilities across a myriad of substances. It’s the go-to method for customized markings on diverse surfaces due to its adaptability.

3. The Magic of Customization

Imagine having your brand logo etched on metal parts with absolute precision. Laser engraving excels in customization, accommodating unique designs, text, or serial numbers as desired. It’s this adaptability that resonates with engineers seeking personalized solutions for their projects.

4. Eco-Friendly & Minimal Waste

In an era prioritizing sustainability, laser engraving emerges as a favorable choice. This process produces minimal waste, minimizing its environmental impact. It doesn’t involve the use of inks or chemicals, making it a greener option compared to traditional methods.

5. The Role of Advanced Technology

Laser engraving isn’t just a craft; it’s a technological marvel. Utilizing cutting-edge CNC machining techniques, this process ensures pinpoint accuracy and consistency across numerous pieces. Its integration with sophisticated technology allows for unmatched precision and quality.

6. Durability in Design

Engravings created via laser technology exhibit remarkable durability. Unlike surface coatings that may wear off, laser-engraved markings withstand the test of time, resisting abrasion and maintaining their integrity over the long haul.

7. Cost-Effective Solutions

While precision engineering often conjures notions of high costs, laser engraving surprises with its cost-effectiveness. Its efficiency in reducing production time and the ability to work with a variety of materials make it a financially viable option.

8. Building Lasting Partnerships

The crux of laser engraving isn’t solely about the technique; it’s about fostering enduring relationships. Companies like CNCPRECISION prioritize not just delivering superior products but also building trust and rapport with clients. It’s this commitment that ensures mutual success and satisfaction.

In conclusion, laser engraving isn’t just an engraving method—it’s a revolutionary technology reshaping the landscape of precision engineering. Its precision, versatility, and environmental friendliness position it as a key player in creating customized, durable, and high-quality metal parts for industries worldwide.