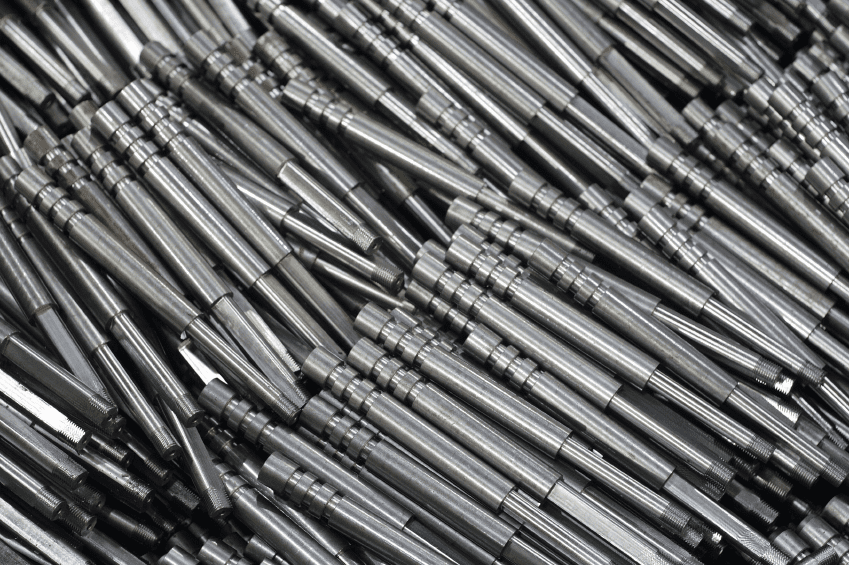

As someone deeply immersed in the world of precision machining, I’m excited to share some insights with you about a critical process that often goes unnoticed – passivation. If you’re passionate about high-quality metal parts and want to ensure their longevity and performance, read on to discover what you need to know about the fascinating realm of passivation.

1. What Exactly is Passivation?

Passivation is like giving your metal parts a superhero suit that protects them from corrosion and environmental factors. It’s a chemical process that involves treating metal surfaces to create a protective layer that prevents rust and enhances their resistance to wear and tear.

2. The Benefits of Passivation

Ever wondered how those stainless steel components in airplanes and medical devices stay shiny and robust? Passivation is the secret sauce. By creating a barrier against corrosion, passivated parts have an extended lifespan, making them perfect for demanding applications that require both durability and precision.

3. Materials that Shine with Passivation

Stainless steel is the superstar when it comes to passivation. But did you know that other metals like titanium and certain forms of aluminum can also benefit from this process? It’s all about enhancing their natural resistance to the elements and giving them that extra edge.

4. Passivation vs. Plating: What’s the Difference?

While both passivation and plating aim to protect metal surfaces, they do so in distinct ways. Passivation alters the chemical composition of the metal surface to create a protective layer, while plating involves adding a layer of another metal onto the base metal.

5. How Does Passivation Work?

The passivation process involves a few key steps. First, the metal parts are thoroughly cleaned to remove contaminants. Then, they’re immersed in a passivation solution that removes iron impurities and encourages the formation of a protective oxide layer. After rinsing and drying, the oxide layer forms, shielding the metal from corrosion.

6. A Match Made in Engineering Heaven: Passivation and Precision Machining

As an engineer who values quality and precision, you’ll be thrilled to know that passivation complements precision machining beautifully. The process doesn’t significantly alter the dimensions of your meticulously crafted metal parts, ensuring that both their structural integrity and surface protection are maintained.

7. Transparency and Tailored Solutions

Just like our dedication to providing tailored solutions for your engineering needs, passivation offers customized protection. You’ll appreciate how passivation solutions can be adjusted to suit different metals and applications, ensuring that the protection is as precise as the machining.

Summary

So there you have it – a crash course in the art and science of passivation. As an engineer who values quality, reliability, and the longevity of your projects, passivation is your secret weapon. It’s the difference between metal parts that withstand the test of time and those that succumb to rust and wear. With passivation on your side, you’re not just creating products; you’re crafting legacies of precision and excellence. Happy engineering!