As an expert in the machining industry, I understand the importance of choosing the right material for your precision metal parts. The material used plays a crucial role in determining the part’s performance, durability, and overall quality. In this comprehensive listicle, I will introduce you to six commonly used materials in machining, providing valuable insights to help you make informed decisions for your projects.

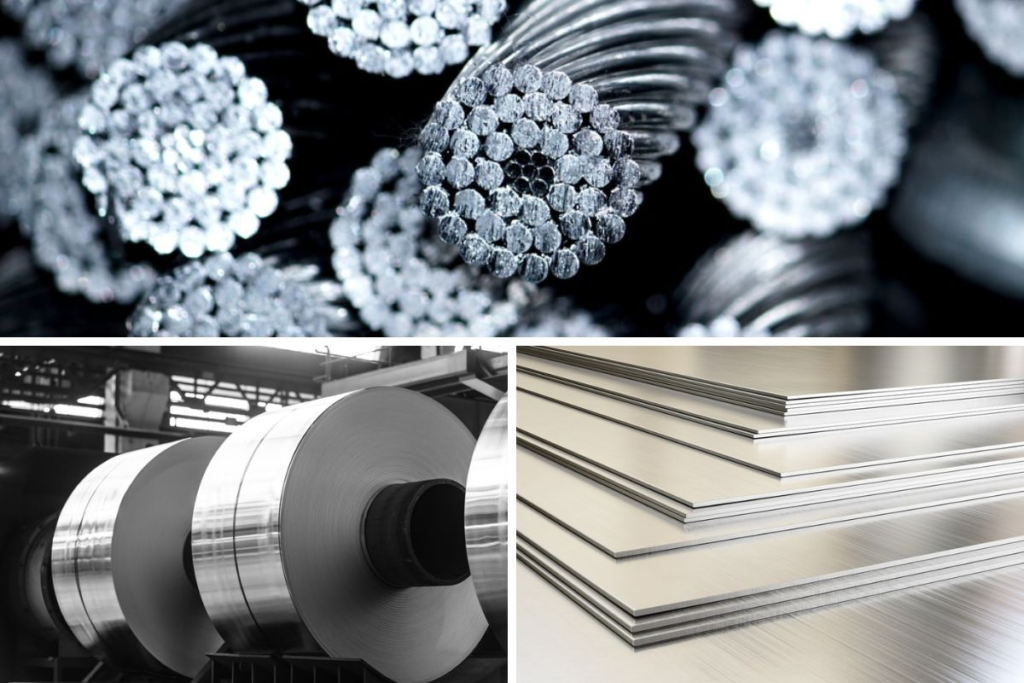

1. Aluminum

Aluminum is a lightweight and versatile material widely used in machining. It offers excellent strength-to-weight ratio, good corrosion resistance, and is easily machinable. Aluminum parts are commonly used in various industries, including automotive, aerospace, and electronics. They are suitable for applications that require high conductivity, thermal management, and low weight.

Summary: Aluminum is a popular choice for machining due to its lightweight nature, strength, and corrosion resistance.

2. Stainless Steel

Stainless steel is renowned for its corrosion resistance, high strength, and durability. It is an alloy of iron, chromium, and other elements, making it resistant to rust and staining. Stainless steel parts are commonly used in industries such as medical, food processing, and marine. They offer excellent mechanical properties, making them suitable for applications that require strength, hygiene, and longevity.

Summary: Stainless steel is a preferred choice for its corrosion resistance, strength, and durability.

3. Brass

Brass is a copper-zinc alloy known for its excellent machinability and aesthetic appeal. It offers good corrosion resistance, electrical conductivity, and low friction properties. Brass parts are often used in applications that require decorative finishes, such as jewelry, plumbing fixtures, and musical instruments. They are also suitable for electrical connectors and fittings.

Summary: Brass is a versatile material with good machinability, corrosion resistance, and aesthetic appeal.

4. Titanium

Titanium is a lightweight and strong material that offers exceptional corrosion resistance, high temperature resistance, and biocompatibility. It is widely used in industries such as aerospace, medical, and sports equipment. Titanium parts are favored in applications that require strength, low weight, and resistance to harsh environments.

Summary: Titanium is an excellent choice for its lightweight, strength, corrosion resistance, and biocompatibility.

5. Carbon Steel

Carbon steel is a versatile and cost-effective material that offers good strength and machinability. It contains varying amounts of carbon, providing different levels of hardness and strength. Carbon steel parts are commonly used in automotive components, machinery, and construction. They are suitable for applications that require strength, durability, and affordability.

Summary: Carbon steel is a cost-effective material known for its strength, machinability, and versatility.

6. Copper

Copper is a highly conductive and malleable material with excellent electrical and thermal conductivity. It offers good corrosion resistance and is often used in electrical and plumbing applications. Copper parts are also utilized in heat exchangers, transformers, and architectural elements. They are ideal for applications that require high conductivity, ductility, and antimicrobial properties.

Summary: Copper is a preferred material for its conductivity, corrosion resistance, and malleability.

In conclusion, choosing the right material for your machining