As an enthusiast and expert in the field of CNC machining, I have had the privilege of witnessing the incredible impact this technology has had on the industrial sector. With its precision, versatility, and efficiency, CNC machining has revolutionized the way we manufacture and produce various components. In this article, I will delve into 10 fascinating applications of CNC machining in the industrial world, showcasing the diverse range of possibilities this technology offers.

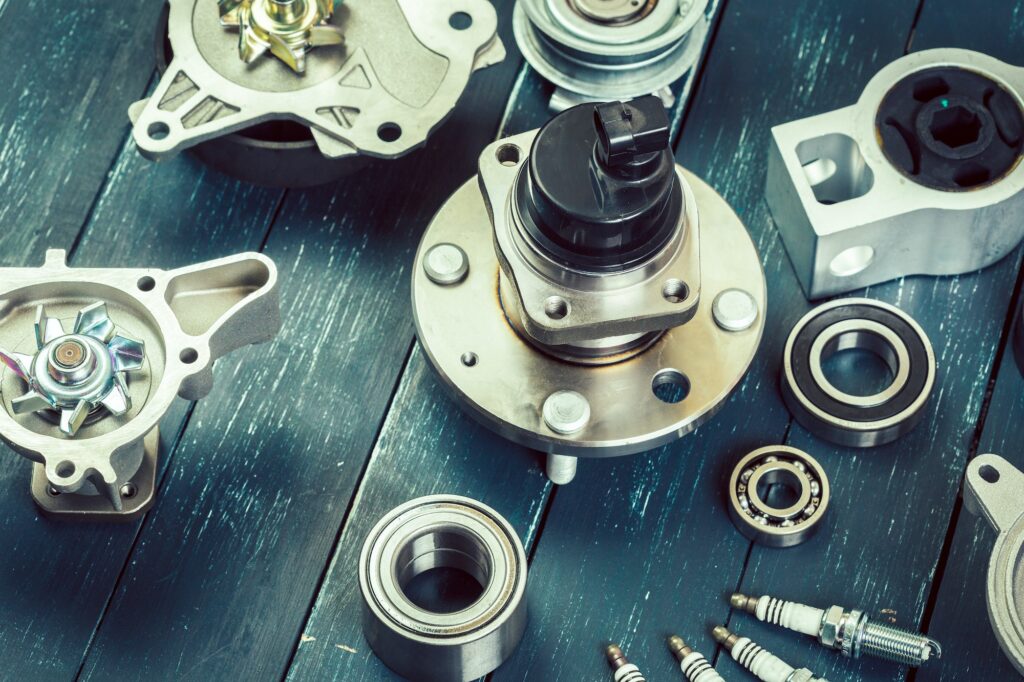

1. Automotive Industry

The automotive industry heavily relies on CNC machining to produce high-quality parts and components with utmost precision. From engine components, transmission parts, and brake system elements to intricate interior and exterior features, CNC machining ensures the consistent production of critical components that meet stringent quality standards. With the ability to work with a wide range of materials, including metals, plastics, and composites, CNC machining plays a vital role in the automotive manufacturing process.

2. Aerospace and Aviation Sector

The aerospace and aviation sector demands uncompromising precision and reliability. CNC machining enables the production of complex aerospace components, such as turbine blades, engine parts, and structural elements, with tight tolerances and intricate geometries. The use of CNC machines ensures consistent quality, reducing the risk of errors and enhancing safety in the skies. The aerospace industry benefits immensely from the versatility and efficiency of CNC machining, enabling advancements in aircraft design and performance.

3. Medical Device Manufacturing

In the realm of medical device manufacturing, CNC machining plays a crucial role in creating intricate and customized components. From surgical instruments and implants to prosthetics and dental equipment, CNC machining allows for the production of precise and biocompatible parts that meet the demanding requirements of the medical field. The ability to work with a wide range of materials, including titanium and stainless steel, ensures the durability and reliability of medical devices.

4. Electronics and Consumer Goods

The electronics industry relies on CNC machining for the production of circuit boards, enclosures, connectors, and other precision components. CNC machines can accurately mill, drill, and engrave intricate patterns and features on electronic components, ensuring their functionality and compatibility. Additionally, CNC machining enables the manufacturing of consumer goods such as smartphones, laptops, and household appliances, where precise dimensions and aesthetics are of utmost importance.

5. Energy and Renewable Sector

CNC machining contributes significantly to the energy and renewable sector by producing components used in power generation and transmission systems. From turbine parts in wind farms to complex components in hydroelectric plants and solar panel manufacturing, CNC machining ensures the precise fabrication of vital elements that drive sustainable energy production. The ability to work with various materials and create intricate designs makes CNC machining an essential tool for advancing renewable energy technologies.

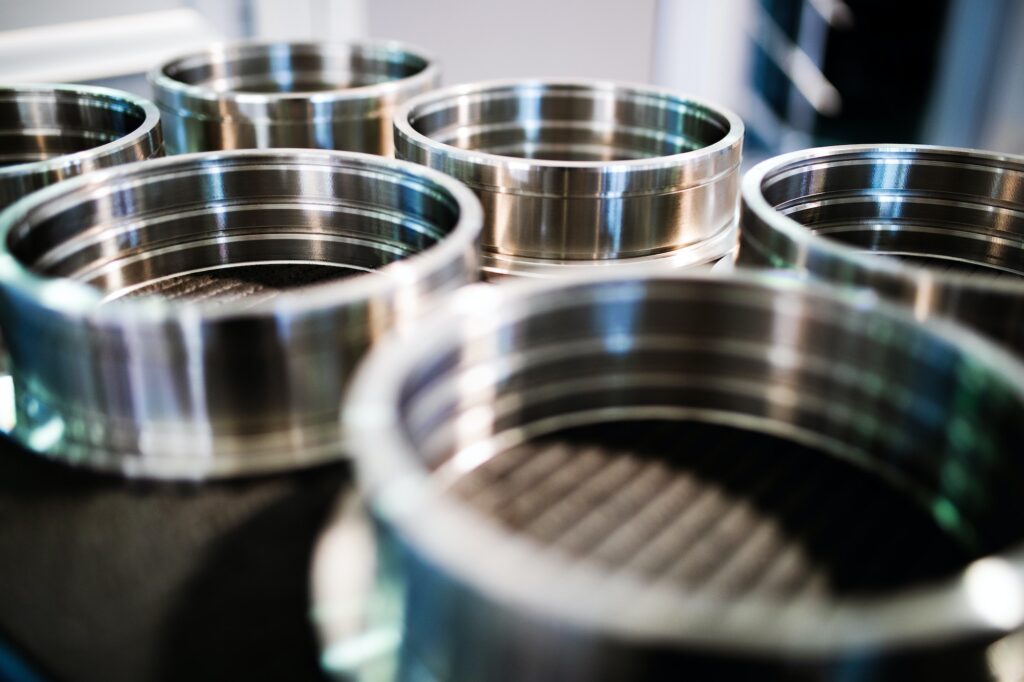

6. Tool and Die Manufacturing

The production of tools and dies requires exceptional precision and durability. CNC machining allows for the creation of intricate molds, dies, and tooling components with tight tolerances. By using computer-aided design (CAD) software, CNC machines can accurately replicate complex shapes and geometries, resulting in high-quality tools and dies that meet the specific requirements of various industries, including automotive, aerospace, and manufacturing.

7. Defense and Military Applications

CNC machining plays a vital role in defense and military applications, where reliability, accuracy, and durability are paramount. From manufacturing firearms and artillery components to producing specialized equipment and military vehicles, CNC machining ensures the precise fabrication of mission-critical parts. The ability to work with hardened materials and create complex designs makes CNC machining an indispensable tool in the defense sector.

8. Industrial Automation

CNC machining plays a significant role in industrial automation by producing components for robotics, assembly lines, and automated machinery. With CNC machines, complex parts required for the automation process can be fabricated with utmost precision, ensuring seamless integration and efficient operation. By leveraging CNC machining in industrial automation, companies can enhance productivity, streamline processes, and achieve higher levels of efficiency.

9. Prototyping and Rapid Manufacturing

CNC machining offers invaluable capabilities in prototyping and rapid manufacturing. By using CAD software and CNC machines, engineers can quickly transform their design concepts into physical prototypes, allowing for thorough testing and validation before mass production. The speed, accuracy, and versatility of CNC machining make it a preferred choice for rapid prototyping, enabling faster product development cycles and reducing time to market.

10. Jewelry and Luxury Goods

CNC machining has found its way into the realm of jewelry and luxury goods manufacturing. The ability to precisely carve intricate designs and patterns on precious metals and gemstones opens up new possibilities for creativity and customization. CNC machines can produce complex filigree work, engravings, and unique jewelry pieces with exceptional precision, catering to the discerning tastes of customers in the luxury market.

Summary

In conclusion, CNC machining has revolutionized the industrial sector with its precision, versatility, and efficiency. From automotive and aerospace industries to medical device manufacturing and electronics, CNC machining plays a pivotal role in producing high-quality components and parts. Its impact is felt across various sectors, including energy, defense, tooling, industrial automation, and even the production of jewelry and luxury goods. With its ability to work with a wide range of materials and create intricate designs, CNC machining continues to shape the future of manufacturing, providing innovative solutions to meet the demands of a rapidly evolving world.